You can crank all day but if your vehicle isn’t starting and you’ve got a crankshaft position sensor fault code then you ain’t going anywhere in a hurry so why not sit back

and together we can run through the diagnostic testing methods used to determine what causes a crankshaft position sensor.

What’s a crankshaft sensor

The crankshaft position sensor (CKP) is a sensor that is used to determine the position of the crankshaft in an internal combustion engine. The CKP sensor is typically located on the crankshaft itself, near the flywheel or flexplate. The CKP sensor sends a signal to the engine control unit (ECU), which uses this information to control ignition timing and fuel injection.

The crankshaft position sensor is typically a magnetic or hall-effect sensor placed close to the engine’s crankshaft. It’s a small but mighty piece of machinery that helps ensure your engine is running properly and efficiently.

It keeps track of the crankshaft’s location and rate of rotation, which is essential data for the engine’s control module. By using this information, the engine may optimize performance and efficiency by adjusting the timing of fuel injection and ignition.

Dirty crankshaft sensor

A dirty crankshaft position sensor (CKP) can cause a variety of problems, including engine misfires, rough idle, and decreased fuel economy. The CKP sensor is responsible for monitoring the position of the crankshaft and sending this information to the engine computer. When the sensor becomes dirty, it can’t accurately measure the crankshaft position, which can lead to the aforementioned problems.

There are a few things that can cause a CKP sensor to become dirty. One common cause is road debris, such as dirt, dust, and mud. This debris can get kicked up by the tires and onto the sensor, causing it to become dirty. Another common cause is oil leaks. If oil leaks onto the sensor, it can cause the sensor to become dirty and malfunction.

If you suspect that your CKP sensor is dirty, you can clean it yourself or have it cleaned by a mechanic. To clean the sensor yourself, you’ll need to remove it from the engine and clean it with a mild soap and water solution. Be sure to dry the sensor thoroughly before reinstalling it.

If cleaning the sensor doesn’t solve the problem, you may need to replace the sensor. The cost of a new CKP sensor varies depending on the make and model of your car.

Causes of crankshaft position sensor problem

This can cause various problems, including:

- Check Engine Light

- Engine Misfires

- Engine Stalling or Difficulty Starting

- Rough idle

- Drivability Issues

Check Engine Light

The check-illuminated engine light on your dashboard will be the most noticeable indicator. Don’t delay – get your car checked out, your car is attempting to alert you that something needs your attention.

Engine Misfires

Your engine will misfire as a result of bad crankshaft sensors and inaccurate fuel injection readings. The engine may stall and be challenging to restart when this issue first shows itself.

Engine Stalling or Difficulty Starting

The engine in your vehicle could have trouble starting or suddenly stall. This is a result of the engine control module receiving inaccurate timing information..

Rough idle

Troubleshooting a rough idle can be tricky, but a bad crankshaft position sensor could be the culprit. When this sensor fails, it can cause your engine to run rough and stall. If you experience this symptom, have an experienced mechanic check your crankshaft position sensor to ensure your engine is running properly.

Drivability Issues

It’s possible that you’ll detect a general decline in performance, decreased fuel efficiency, or weird noises coming from the engine.

You must pay attention to these warning signs.

How to repair a crankshaft position sensor

In most cases, the only way to fix a bad crankshaft position sensor is to replace it. However, there are a few things you can do to try to repair it before you replace it.

- Check the wiring. The first thing you should do is check the wiring to the crankshaft position sensor. Make sure that the wiring is not damaged and that all of the connections are tight. You’ll need to repair the wiring if it is damaged.

- Clean the sensor. If the wiring is not damaged, the next thing you can try is to clean the sensor. The crankshaft position sensor can become dirty over time, which can cause it to malfunction. To clean the sensor, you’ll need to remove it from the engine and clean it with a mild soap and water solution. Be sure to dry the sensor thoroughly before reinstalling it.

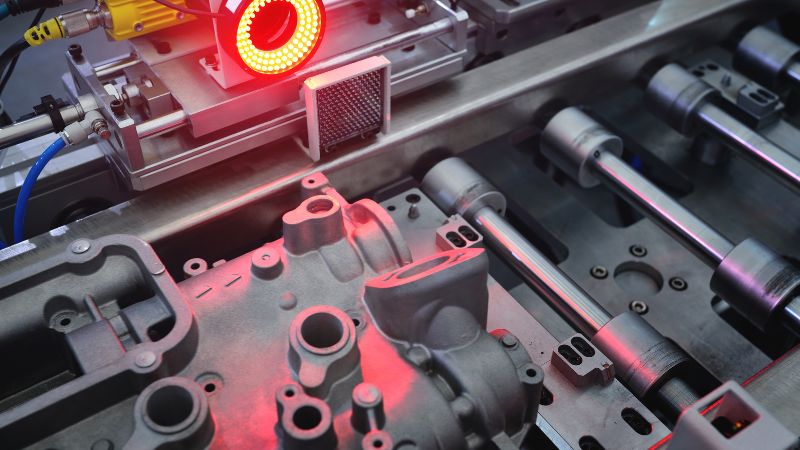

- Replace the sensor. If cleaning the sensor doesn’t work, you’ll need to replace it. First carefully remove the crankshaft position sensor from the vehicle. To ensure that the sensor hasn’t been polluted by a leak from another engine part, visually inspect it. Use a multimeter to proceed with a resistance test on the crankshaft position sensor. In order to get a correct reading check your owner’s manual to see the specific crankshaft position sensor resistance range for your vehicle. If you don’t get a reading this indicates that the crankshaft position sensor is faulty and needs to be replaced. Check to make sure the o ring from the sensor hasn’t fallen into its hole then replace it with a new crankshaft position sensor. So here is one method to fix the crankshaft position sensor.

If you’re not comfortable replacing the CKP sensor yourself, you can take your car to a mechanic. They will be able to replace the sensor for you.

How to reset the crankshaft position sensor

To reset a crankshaft position sensor that won’t start, you will need to follow these steps:

- Turn off all accessories in your vehicle.

- Accelerate to 55 mph and maintain that speed for 5-6 minutes.

- Once you have reached 45 mph without using the brakes, maintain that speed for one minute.

- After one minute, turn off your engine and restart it.

If your vehicle still won’t start, you may need to have the crankshaft position sensor replaced.

Here are some additional tips for resetting a crankshaft position sensor:

- Make sure that the engine is at its normal operating temperature before you begin the reset process.

- If you have a scan tool, you can use it to check for any codes that may be related to the crankshaft position sensor.

- If you are not comfortable resetting the crankshaft position sensor yourself, you can always take your vehicle to a qualified mechanic.

FAQ

Q. How to reset the crankshaft position sensor without a scanner?

In most cases, you cannot reset a crankshaft position sensor without a scanner. However, there are a few models of vehicles that have a built-in procedure for resetting the sensor. If you are not sure if your vehicle has this feature, you can consult your owner’s manual.

If your vehicle does not have a built-in procedure for resetting the crankshaft position sensor, you will need to use a scanner to do so. There are many different scanners available on the market, and they all work slightly differently. However, the basic steps for resetting the crankshaft position sensor are the same:

- Turn on the scanner and connect it to the vehicle’s diagnostic port.

- Select the “Crankshaft Position Sensor Relearn” option from the scanner’s menu.

- Follow the on-screen instructions to complete the relearn process.

Q. What to do after replacing the crankshaft sensor?

After replacing your crankshaft sensor, there are a few things you should do to ensure that it is working properly.

- Check for codes. Use a diagnostic tool to scan for any codes that may have been triggered by the sensor replacement. If there are any codes, clear them and see if they come back.

- Start the engine and let it idle. Listen for any unusual noises or vibrations. If you hear anything, turn off the engine and check the sensor installation.

- Drive the vehicle. Pay attention to how the engine runs. If you notice any problems, such as rough idle, loss of power, or check engine light, take the vehicle back to the mechanic who replaced the sensor.

Q. How to clean up a crankshaft position sensor?

Here are the steps on how to clean up a crankshaft position sensor:

- Locate the crankshaft position sensor. It is usually located on the front of the engine, near the crankshaft.

- Disconnect the electrical connector from the sensor.

- Use a socket wrench and ratchet to loosen the sensor.

- Remove the sensor from the engine.

- Use a wire brush to clean the sensor’s contacts.

- Blow the sensor with compressed air to remove any dirt or debris.

- Wipe the sensor with a clean rag.

- Reinstall the sensor and connect the electrical connector.

Final Word

So here is the essential information to fix your crankshaft position sensor, at least temporarily. Now you can drive smoothly move forward confidently and continue making progress.